Q400 DIC - System for Full field Deformation and Strain Measurement

|

|

|

| With the Q400 system, the 2D or 3D deformation analysis is performed in a precise, fast and user-friendly manner. The modular system is also characterized by the high flexibility of the optical setup and thus can be optimally adapted to the application. The intuitive measurement software Istra4D also provides the associated measurement accuracy for each measured value (displacement, deformation, strain, 3D coordinates, etc.). Thanks to optimized algorithms, Istra4D can resolve local effects, e.g. in crack growth, better than other DIC systems. Using a special cluster approach, up to 16 cameras can be used in a Q400 system, which achieves better surface coverage for complex component geometries and higher measurement accuracy. |

Features

|

Technical Specifications

| System type |

Description | Applications |

| Q400-2D | 2D-DIC "Entry system" with one camera | Measurement at flat specimen |

| Q400-3D | 3D-DIC Stereo system | Measurement on all surface geometries |

| Q400-EDU | 3D-DIC system for educational institutions | Flexible system for academic teaching and internships |

| Q400-TRIPLE | 3D-DIC system with 3 cameras | Higher measurement accuracy than with 2 cameras Better surface coverage at complex object geometries |

| Q400-4CAM | 3D-DIC system with 4 cameras (2x 2 cameras) | For the measurement of the strain distribution at material tests. Simultaneous measurement of the strain distribution at front and back side and thickness, thickness change and volume. |

| Q400-MultiCAM | Multi camera system | Better surface coverage at complex object geometries 8 cameras for 360° measurement of cylindrical objects |

| Q400-µDIC | DIC system with stereo microscope | Measurement at small FOV (0,5 x 0,5mm to 17x17mm) |

| Q400-Vibro | Combination of Q400 and trigger unit PhaseTriggerLS (Strobe-CAM) | For vibration measurement, mode shapes, fatigue tests |

| Q450 | Systems with high speed cameras | For dynamic applications and for vibration measurement at non periodic excitations |

Due to our modular concept the systems can be upgraded with additional cameras.

Characteristics (depending on the selected system hardware):

| Field of View | 1mm² to 100m² (with standard lenses) |

| Precision for 3D displacements | 0.01 pixel (corrsponds to 1µm with 1Mpixel camera and 100x100mm FOV) |

| Precision for strain | 50 µstrains (=0.005%) @ spatially resolved measurement 5 µstrain as extensometer |

| Strain measurement range | 1µstrain to 1000% |

| Camera resolution | 0,3 Mpixel (VGA) to 48 Mpixel |

| Acquisition rate | Statische Systeme: 1Hz bis ca. 100Bilder/s Midspeed-Systeme: bis 560Hz bei 4MPixel Kamera-Auflösung Highspeed-Systeme: bis 2.000.000 Bilder/s |

| Real time analysis | Optional software module |

Applications

|

The applications field of the Q400 systems is very wide spread.

It can be measured on nearly all materials like: wood, metals, plastics, (metal) foams, rubber, composites, paper, etc. Typical applications:

To the list of scientific articles in which the Q400-System was used. |

Applications examples categories: |

Measurement principle DIC (Digital Image Correlation)

| Measuring principle: One or more digital cameras record the deformation process. The object surface has a stochastic (natural or prepared) pattern ("speckle pattern"). The images are automatically evaluated using subpixel-accurate digital image correlation algorithms. This assigns the local surface pattern to the camera pixels and measures 3D coordinates, 3D displacements, 3D deformations and surface strains components. |

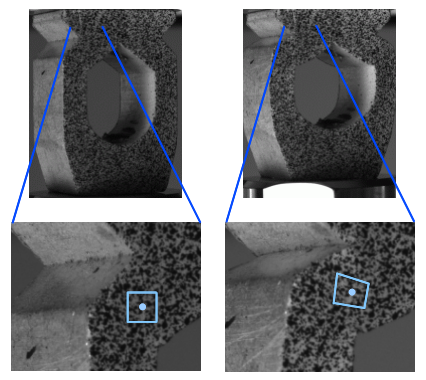

Pattern recognition

Digital image correlation is a camera based technique for the measurement of deformations on object surfaces. The method tracks the grey value pattern (speckle pattern") in small neighborhoods ("subsets" or "facettes") shown light blue in the camera images.

Reference state vs. deformed state Reference state vs. deformed state |

Spatially Resolved Measurement

The analysis of images and sequences with digital image correlation allows the measurement of displacements and deformations at every camera pixel. The resulting fullfield information is very comprehensive and has many advantages compared to other measurement techniques.

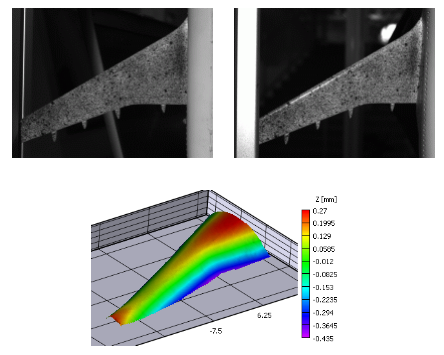

The images show the speckle pattern of an object without and with deformation and the measured strain distribution.

Undeformed state

|

Deformed state

|

Strain distribution

|

|

|

|

3D DIC

During the object deformation stereo images are recorded with two cameras. The stereo correlation between the left and right images measures the geometry and position of the object at every load stage.

The two shown images are recorded simultaneously with the left and right camera of a stereo system.

3D geometry by stereo correlation

|

Time Course

The temporal correlation between reference state and deformed state calculates the 3D displacement and 3D deformation of the object.

Strain calculation by stereo correlation and temporal crrelation. Strain calculation by stereo correlation and temporal crrelation. |

Software

| Software | Functionality |

| Istra4D |

Modular software package with integrated

Import and export of external image sources (e.g., high-speed camera, microscope) Visualization of the spatially resolved measurement results as a 2D color overlay or as a 3D representation Data display on points, lines, polygonal lines as well as circular and polygonal areas Definition of "virtual strain gauge" Definition of "virtual extensometers" with a definable length Temporal diagram plots of variables Spatial variable diagrams of polygonal line sections Multiple possibilities of data export (ASCII, STL, HDF5) Generation of AVI videos and image export of results Integrated analysis modules (scripting):

|

Document-Downloads

Brochure:

Paper:

Image correlation, strain sensor and strain measurement in industry

Image correlation or digital image correlation is a proven method for measuring the smallest displacements and strains. It is generally based on the digital image analysis of a series of images taken during the deformation of the object under study, with the aim of identifying areas of similar appearance in different images. This method can be used to measure very small displacements that cannot be detected using other means.

Strain measurement at a glance

There are many different types of strain sensors, each with its own advantages and disadvantages. The most common type is the piezoelectric strain sensor, which converts mechanical energy into electrical energy. Other types of strain sensors include strain gauges, optical fiber Bragg grating sensors and carbon nanotube sensors.

Strain measurement involves measuring the magnitude and direction of an object's deformation. This can be done through direct or indirect methods. The direct method involves measuring deformation directly using a measuring device such as a micrometer or digital caliper. In the indirect method, the deformation is derived from other measurements, e.g. from changes in length, width or thickness.

Strain measurement is used in many different industries for quality control and monitoring. It is particularly important in the automotive industry, where it is used to monitor the manufacturing process of auto parts and ensure compliance with safety standards. Strain measurement is also used in the aerospace industry to monitor aircraft parts during manufacturing and testing.

Often safety-relevant: strain measurements, image correlation, etc.

Image correlation, strain sensor and strain measurement are all essential tools in many industries. With their help, engineers and technicians can ensure the quality of products, machines and designs and thus also the safety of users.

Major strain E1 of the image sequence.

Major strain E1 of the image sequence.