RTSS Videoextensometer - Contactless Strain Sensor for Material testing

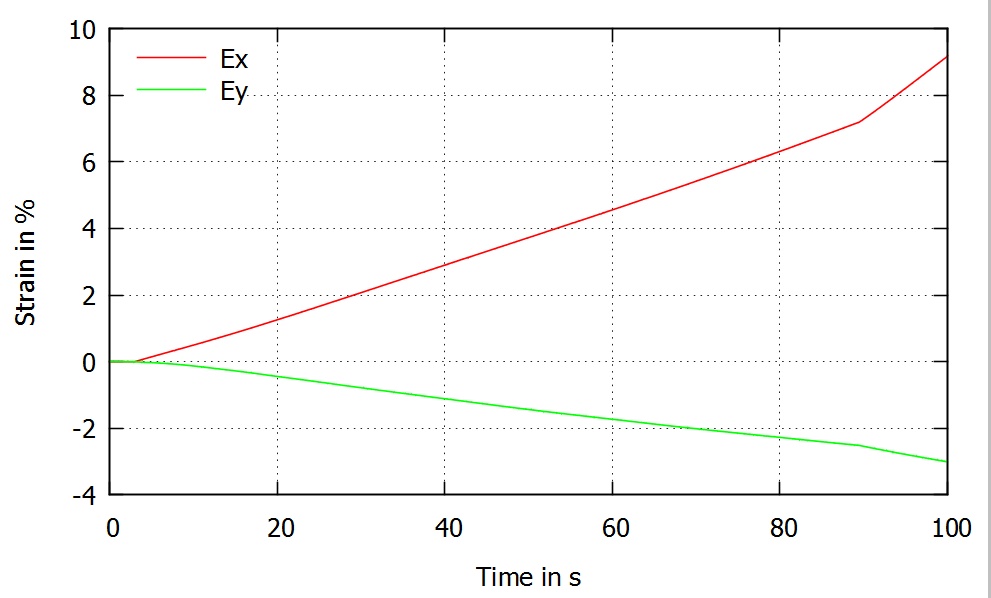

Precise and flexibleWith the RTSS video extensometer, longitudinal strain and transverse strain are measured contactlessly during material testing. The optical strain sensor is used in tensile, compression, fatigue and creep tests and is suitable for flat samples, round samples, wires, reinforcing steel, etc. |

|

|

|

Compatible to universal test machines (UTM)The RTSS (Real Time Strain Sensor) can be integrated via different interfaces as a strains sensor and can be used with any test machine on the market. |

|

Features

|

Technical Specifications

Product-Variants:

| RTSS_Cx: | High resolution video extensometer for quasistatic tensile tests. Measurement resolution for strain down to 5µstrains (=5µm/m) |

| RTSS_HS: | Fast video extensometer for dynamic tests. The high measurement rate makes the system suited for dynamic applications (e.g. on a Hydropulser) and for the control of fast test. |

| RTSS_CREEP | Simultaneous measurement of up to 10 specimen with a single high resolution camera that captures all specimen at the same time. This system is typically used for crep testing applications.. |

| Multi-camera-Systems: | Multi camera setups for:

|

| Specifications \ System | RTSS_C1 | RTSS_C05 | RTSS_C02 | RTSS_HS |

| Precision class (ISO9513) at 100mm FOV* |

1 | 0,5 | 0,2 | 1 |

| Strain resolution | 0.002% | 0.001% | 0.0005% | ca. 0,002% |

| Distance resolution at 100mm FOV* |

1µm | 0,5µm | 0,2µm | 1µm |

| Gauge length L0 | 10-1000mm | 10-1000mm | 10-1000mm | 10-200mm |

| Measurement rate | up to 100Hz | up to100Hz | up to 100Hz | up to 1000Hz |

*FOV=Field of View=image width. The FOV can be adjusted through different lenses.

We configure also individual systems for special applications.

Applications

|

The RTSS Videoextensometer is used as strain sensor

To the list of scientific articles in which the RTSS system was used. |

Software

| Software | Functionality |

| RTSS |

Flexibly configurably real time measurement software

Multi-Core Support

|

| Istra4D | Optional post-processing software for

|

Documents-Downloads

Leaflets: