Dimensional quality control of a large steam turbine housing using a laser scannerFor the dimensional quality control against the CAD model, the entire housing half (inner and outer surfaces) of a low-pressure steam turbine (Siemens AG / Mühlheim) is completely digitalized in 3D. |

Report about the 3D digitisation of a steam engine housing

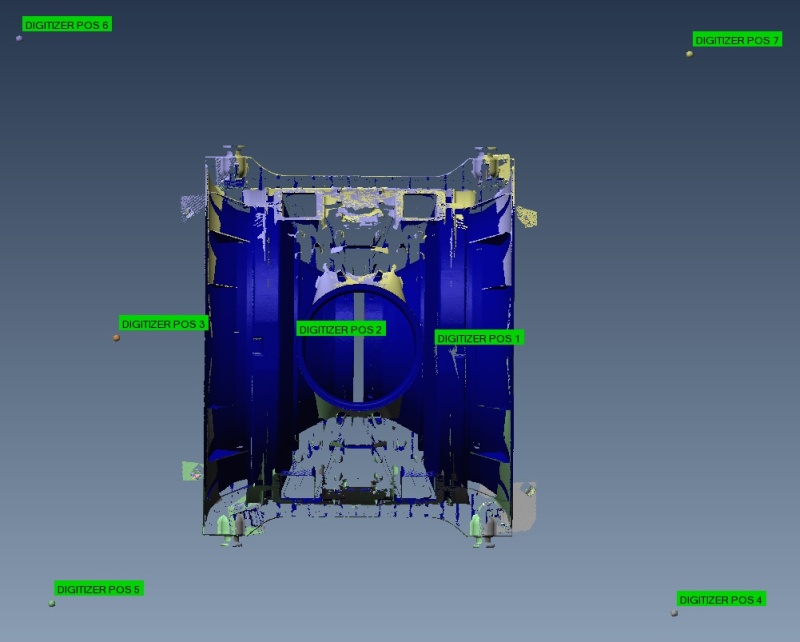

For the proof of dimensional stability against the CAD model it is necessary to scan the inside as complete as possible and to scan the outside at relevant areas. A sufficient coverage is achieved with a total of 7 scans: One front scan (Figure 1, pos. 3), two scans from underneath and 4 horizontal scans at the corner positions (pos. 4-7).

Figure 1: The top view shows the 7 scan positions. The positions 1-3 are from underneath to scan the internal surface.

Figure 2: Housing half with Surphaser underneath (at scan position 1 of 7).

10 contrast targets are distributed in the scan volume for the referenzing of the scans against each other. Figure 3 (animation) shows the outside scan images with the automatically extracted target positions.

The scans are automatically referenced in the post processing software.

Figure 3: Some scan data images with referencing targets.

| Summary | |

|

• Scanner |

Surphaser HSX100-SR |

Courtesy of Siemens AG / Muehlheim.

Figure 4: Animation of the merged point cloud. (Visualized are only 10% of the data set)