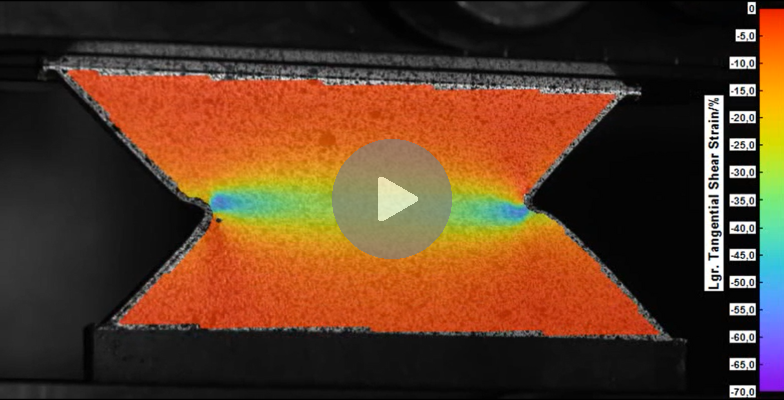

Measurement of the shear strain at a shear testThe Q400 DIC system measures the shear strain and other strain components fullfield. Why are shear tests carried out?Shear tests help determine the shear strength and shear modulus of a material. These parameters are important for understanding the behavior of a material under shear loading, which in turn helps in selecting the appropriate material for specific applications. Quality Control: Manufacturers conduct shear tests to ensure that their products have the required mechanical properties. These tests enable potential defects or weak points in the material to be identified at an early stage. Design optimization: Engineers use the results of shear tests to optimize the design of components and structures. This can help improve the strength and stability of products while reducing material and manufacturing costs. Research and development: In materials science and other scientific fields, shear tests are carried out to investigate the behavior of materials under shear stress and to gain new insights. This contributes to a better understanding of materials science and can lead to the development of new materials. Reliability assessment: Shear tests can also be used to assess the reliability and service life of components and structures. By studying the shear behavior of a material, engineers can make predictions about its behavior under different loading conditions. Overall, shear tests are an important tool for understanding the mechanical properties of materials and ensuring that they meet the requirements of different applications. |